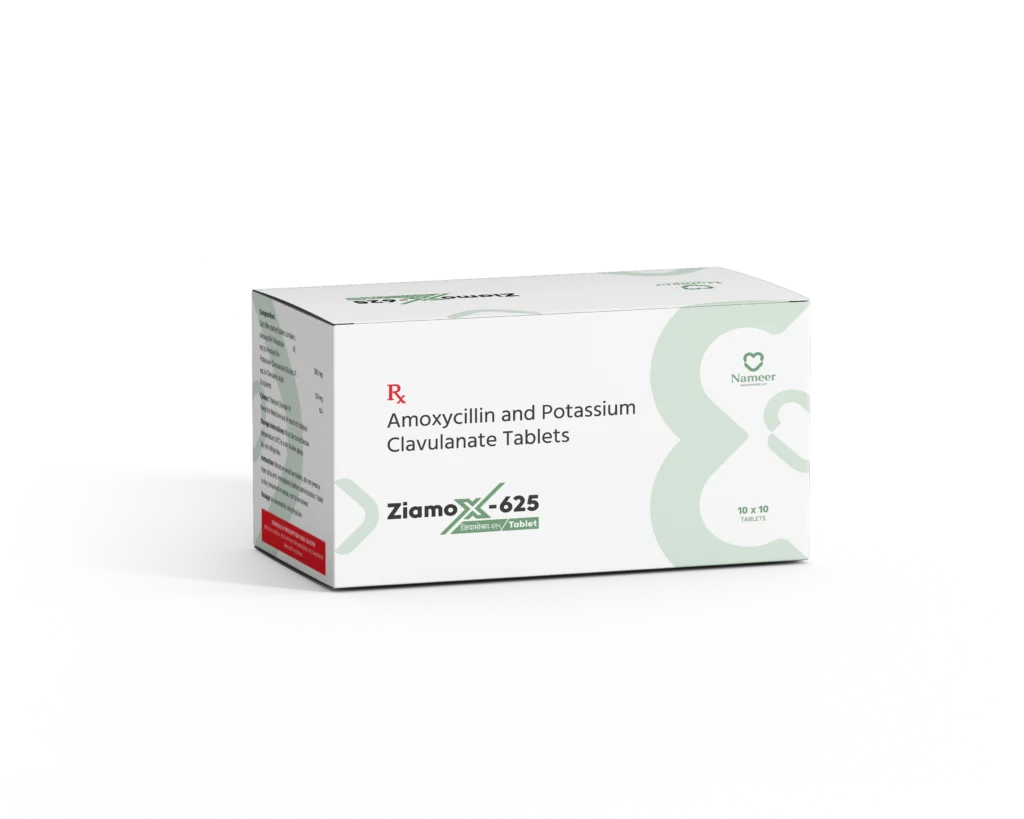

ZiamoX-625

Home >> Products >> Ziamox-625

Ziamox-625

ZiamoX-625 Tablet is a broad-spectrum antibiotic combination containing Amoxycillin and Potassium Clavulanate. It is effective against a wide range of bacterial infections by inhibiting bacterial cell wall synthesis and overcoming resistance caused by beta-lactamase producing organisms.

Each film-coated tablet contains:

- Amoxycillin Trihydrate I.P.

Equivalent to Amoxycillin — 500 mg - Potassium Clavulanate Diluted I.P.

Equivalent to Clavulanic Acid — 125 mg - Excipients: q.s.

- Colour: Titanium Dioxide I.P

- Upper and lower respiratory tract infections

- Ear, nose & throat (ENT) infections

- Urinary tract infections

- Skin and soft tissue infections

- Dental infections

- Bone and joint infections

- Other infections caused by susceptible bacteria

As directed by the physician.

Medicine Production Process

01

Research & Development (R&D)

New drug molecules are discovered, tested, and optimized for safety, efficacy, and stability.

02

Pre-Formulation Studies

Understanding the drug’s physical, chemical, and biological properties to design the right dosage form.

03

Formulation Development

Creating the final dosage form (tablet, capsule, injection, etc.) with excipients to ensure effectiveness.

04

Raw Material Procurement

High-quality active pharmaceutical ingredients (APIs) and excipients are sourced under strict compliance.

05

Weighing & Dispensing

Precise measurement of raw materials to maintain consistency and quality in every batch.

06

Granulation / Mixing

APIs and excipients are blended or granulated to achieve uniformity for tablet or capsule production.

07

Compression / Filling

The mixture is compressed into tablets or filled into capsules with accuracy.

08

Coating / Finishing

Tablets may be coated for taste masking, controlled release, or product stability.

09

Sterilization (for Injectables)

Parenteral products undergo sterilization to ensure they are safe and free from contaminants.

10

Quality Control (QC) Testing

Each batch is rigorously tested for purity, potency, safety, and compliance with regulatory standards.

11

Packaging

Medicines are packed in blisters, bottles, or sachets with labeling and batch details for traceability.

12

Storage & Distribution

Finished products are stored under controlled conditions and distributed through the pharma supply chain.